|

Our multi-axial scrims are non-woven and are bonded via coating

individual yarns, using a small coated yarn to bond the dry scrim together prior

to assembly, coating dry scrim via dip-coating, kiss-coating or laminating to a

variety of films or mats. End uses include sail cloth reinforcement, ballistics,

marine products, wind blades, etc.

The process for the manufacture of multi-axial scrims was developed

and built by Ply-Tech and is very versatile and almost unlimited as to

constructions. Wide widths unimaginable in conventional manufacturing are

possible with our process. If there is a need for 30 foot wide scrim - we can

build a machine to make it that wide.

Click on any picture for a larger view.

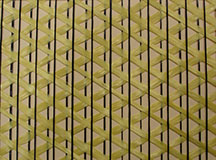

2.0oz/yd˛ 75/1/0 Fiberglass yarn

1.57oz/yd˛ 150/1/0 Fiberglass yarn

EVA coated

EVA coated

2.98oz/yd˛ 300Tex roving Fiberglass

EVA coated

0.66oz/yd˛ 3K Carbon EVA coated

0.80oz/yd˛ 1500 denier Technora™

0.80oz/yd˛ 1500 denier Technora™

EVA coated

EVA coated

4.6oz/yd˛ quad axial construction

650 denier Spectra™ in +/- 45̊

1.0oz/yd˛ quad axial construction

12K Carbon in the 90̊ and 200

500, 840, 1000 denier polyester

denier polyester plus carbon at 0̊

EVA coated

EVA coated

1.5oz/yd˛ 1140 denier Aramid

0.90oz/yd˛ 1000 denier Aramid

EVA coated

EVA coated

5.2oz/yd˛ 3000 denier Aramid

0.50oz/yd˛ 400 denier Aramid

250 denier polyester in the warp

EVA coated

EVA coated

2.97oz/yd˛ 2x3000 denier dry Aramid.

5.04oz/yd˛ 2x3000 denier dry Aramid.

150 1/0 Fiberglass EVA coated in the

150 1/0 Fiberglass EVA coated in the

warp

warp

0.83oz/yd˛ 1140 denier Aramid

3.2oz/yd˛ 7200 denier Aramid

750 denier Technora™ in the warp

750 denier Technora™ in the warp

EVA coated

EVA coated

Web site and all contents © Copyright Ply-Tech, Inc. 2008 All rights reserved.

830-625-3913 - Voice 830-626-3782 -

Fax

|